Process optimisation through a connected ecosystem

Industry 4.0 (I4.0) is a new trend of automation and data exchange in manufacturing technologies. It creates a connected ecosystem for manufacturing, integrating computing, networking, and physical processes.

On the production floor, each machine, robot, component, and the final product itself has a digital model, connected through data that is shared on cloud. This allows for real time monitoring, control, and optimisation. With increasing demand from global and regional markets, embrace this transformation to expand overseas and stay competitive.

With I4.0 as part of your global expansion process, we work with you to identify market demand and technology sources that your business can co-partner for overseas operations.

How I4.0 works

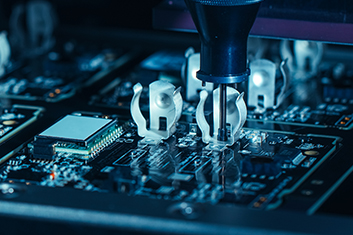

Through I4.0, an assembly factory of the future looks like this:

- After an order is received, an Automated Mobile Robot automatically picks up components from storage, batches them up, and sends them to each workstation;

- Autonomous robots assemble these parts, working in collaboration with humans, while advanced visual technologies track the quality in real time;

- When an urgent order comes in, the cloud-based planning system automatically adjusts the whole manufacturing schedule, optimising the flow and meets all order deadlines.

This transformation does not end on the production floor, but involves the entire process. For example, product design and engineering processes can be entirely digitalised with the help of advanced simulations, allowing teams in different geographical locations to collaborate and co-share resources. Spare parts can be ordered automatically and delivered with improved just-in-time logistics. Products can also communicate with manufacturers after being delivered to the clients, who could monitor the operating status and predict maintenance requirements. After this entire cycle, the data collected can be used to optimise designs of future models.

Impact of I4.0

I4.0 transforms the manufacturing process in the following ways:

- At the factory level, it provides better optimisation and flexibility to the manufacturing process

- At the ecosystem level, the entire manufacturing process could run on a common platform, allowing:

- Supply chain stakeholders to seamlessly exchange data and coordinate their activities;

- Clients to purchase “Manufacturing-as-a-Service”– the shared use of a manufacturing infrastructure – where jobs are allocated to manufacturers with the right capability and capacity;

- 3rd party service providers (e.g. logistics, bank, insurance) to offer customised services based on big data analytics.

Adopting I4.0

I4.0 is essential for manufacturers competing in international markets. Due to reasons such as rising cost, a lack of trained manpower for overseas operations, competition from lower cost countries, and higher requirements in turnaround speed and flexibility from global customers, many companies have only implemented a limited level of automation.

Embark on your I4.0 journey to:

- Find new revenue streams by transforming business models and expanding into a new business area (e.g. software integration);

- Tackle manpower shortages through enhancing productivity, and meet clients’ needs by optimising the manufacturing process;

- Gain capabilities to serve more global customers with higher requirements, while supervising matters from Singapore;

- Create value-added jobs for Singaporeans to support your expansion overseas; and

- Compete in markets beyond precision engineering, like textile, food, semiconductor, and electronics, as your business ventures into global markets.

The Smart Industry Readiness Index

Developed by the Singapore Economic Development Board (EDB)

SIRI comprises a suite of frameworks and tools to help manufacturers – regardless of size and industry – start, scale, and sustain their manufacturing transformation journeys.

Learn more about the SIRI

Centre of Innovation for Electronics & Internet of Things (COI-EIoT)

The Centre of Innovation for Electronics & Internet of Things (COI-EIoT)

Gain access to partnership networking activities that encourages innovation sharing and collaboration, assists in manpower training, and facilitates funding.

Standards for I4.0

Embark on your I4.0 journey and consider adopting standards to optimise efficiency, quality & assurance, as well as speed and flexibility.

Standards can support you in the adoption of I4.0 technology. Some examples include:

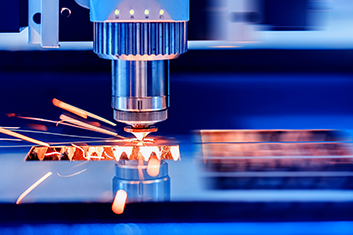

- Additive Manufacturing

- Cybersecurity and Connectivity for Digital Factories

- Industrial and Collaborative Robots

- Digital Twinning

Aligned with the Smart Industry Readiness Index (SIRI), the Standards for Industry 4.0 tool is a guide on key standards, use cases, training courses and more to support you in adopting I4.0 solutions in your business.