Browse programmes and initiatives

-

All

-

Financial Support

-

Innovation

-

Market Access

-

Productivity

-

Talent Attraction & Development

Key opportunities

-

Industry 4.0

-

Semiconductors

-

Robotics

-

Medical Technology (MedTech)

Modern manufacturers are adopting smart technology and artificial intelligence to replace laborious work in their factories.

Bank on Singapore’s reputation as a smart nation to improve manufacturing processes and support businesses. Through smart technology solutions, seize opportunities to build strong engineering design capabilities with product ideation, design and prototyping.

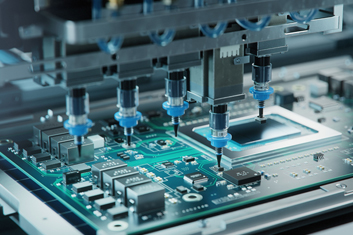

Smart factories equipped with advanced sensors, embedded software and advanced technologies collect and analyse data to allow for better decision making. Combine this with ERP, supply chain, customer service and other enterprise systems to create new levels of insights and visibility on previously siloed information. These efficiency gains and responsiveness will allow you to stay agile and prepared to pivot when challenges arise.

Leverage on Enterprise Singapore’s partner network to experiment, co-develop new solutions and redefine work processes through Industry 4.0 (I4.0), a new trend of automation and data exchange in manufacturing technologies.

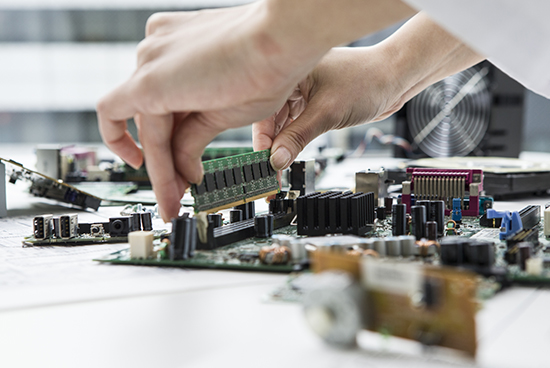

Manufacturers create parts, components and equipment that are essential to the semiconductor manufacturing lifecycle, supporting our fabs, front end and back-end processes.

Singapore is a key hub for semiconductor manufacturing, comprising 11% of the global Semiconductor Market and 7% of Singapore’s GDP. Our processors and memory chips are used in applications as varied as 5G and autonomous vehicles, to data centres powering our cloud services, catalysing the rapid advancement of cybersecurity, automation, connectivity and sustainability.

Singapore provides a conducive business environment with a holistic ecosystem for semiconductors. Companies undertaking chip manufacturing have access to a good base of talent and robust supplier network. Companies can also network through trade associations like Singapore Semiconductor Industry Association (SSIA), and develop technical competencies through R&D partners like A*STAR’s Institute of Microelectronics.

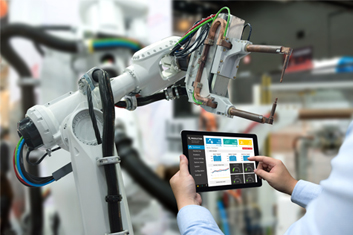

Explore i4.0 through the use of robotic manufacturing solutions.

Singapore has the second highest robot-to-worker density in the world. The pandemic has sped up the acceptance and adoption of robotics, solving emerging challenges like labour shortages as well as high risk jobs.

Applications of industrial robots have expanded past simple robotic arms in manufacturing and logistics, and into specialised and humanoid robots serving the healthcare, built environments, retail and construction industries. Autonomous Guided Vehicles (AGV) and Autonomous Mobile Robots (AMR) are deployed commonly to fill roles traditionally performed by humans in a factory.

Companies can work closely with National Robotics Programme (NRP) to build and innovate technology, or network in the marketplace of ideas with industry leaders like Singapore Industrial Automation Association (SIAA).

Precision engineering has enabled medical breakthroughs today that would not have been possible without the advent of new and innovative technologies and products.

Advanced economies are seeing rising rates of chronic disease due to unhealthy lifestyle habits and rapidly aging populations. Singapore itself is no exception to the rule, where 1 in 5 of the population is above 65. MedTech manufacturing has grown to $19 billion in production output, more than five times the output in 2008, underlining Singapore’s role as a critical manufacturing base producing a diverse range of medical technology products, from implantable pacemakers, to contact lenses and life science instruments for global markets.

Enterprise Singapore can support your MedTech journey to develop capabilities, innovate and internationalise. Adopt quality assurance standards to unlock a broad spectrum of customers with MedTech needs. Look forward to working with global leaders including the world’s top universities, healthcare institutions and research institutions.

Get recognised for consistent quality through standards

Adopting standards is an effective way for your company to maintain consistent quality, build customer trust and gain acceptance in global markets.

Use recognised standards for your business and assure your customers that you have met local and international benchmarks for good quality.

Is your business staying competitive?

Launched in 2022, the Precision Engineering Industry Transformation Map (ITM) prepares manufacturing sectors for global competition by encouraging retailers to adapt and innovate to remain relevant.

Explore the ITM to understand the core strategies at work, the initiatives and schemes to drive innovation and technology adoption, and upskill your workforce to take on better jobs and improve productivity.

Ways to expand your business in precision engineering

-

Key Markets | Precision Engineering

Find out more about the key markets for precision engineering and how you can reach them through the right networks and resources.

-

Guides & Insights | Precision Engineering

Upgrade your business capabilities with our tools and stay up to date on the latest precision engineering.

-

Industry Partners | Precision Engineering

Work closely with industry associations and partners to grow your business in precision engineering.

-

Transform your manufacturing processes through connected ecosystems and automation.